Weldment: Trims

SolidWorks

offers many tools that enable engineers to design innovative parts. These tools range from basic feature

creation, to specialized tools such as weldments. A weldment is an object made of many parts

welded together. This can include but

not limited to structural sections and plates.

The base concept of SolidWorks Weldment involves creating a base layout

sketch and filling in the sketch with structural members.

When a structural member is applied it will

most likely require trimming to fit the intended profile. The Trim Tool is an invaluable tool to

accomplish this task. Trim has many

similarities to sketch trim where it allows the user to change the end

condition for each structural member. If

a member is too long or too short it may adjust it to suit.

However it is also worth noting that trim can

be used in more creative ways as well.

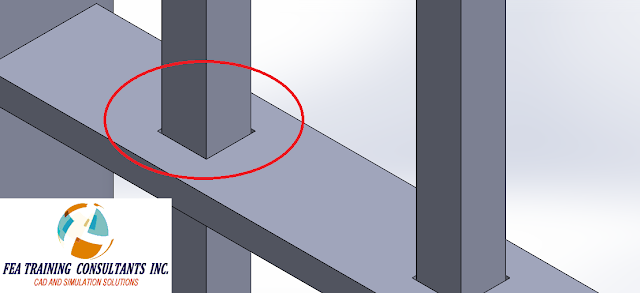

Consider a simple fence as shown below:

The fence is

fully modeled in weldments; however the pickets are placed such that they are

intersecting the crossbar thereby creating interference.

We can use

the Trim tool within weldments to correct this interference. By activating Trim and setting a weld gap,

the program cuts a hole into the cross bar that includes a clearance the size

of the specified weld gap.

Not only can

trim be used to adjust and modify structural member end conditions, but it can

also create new features within a part such as a hole with clearance.

No comments:

Post a Comment