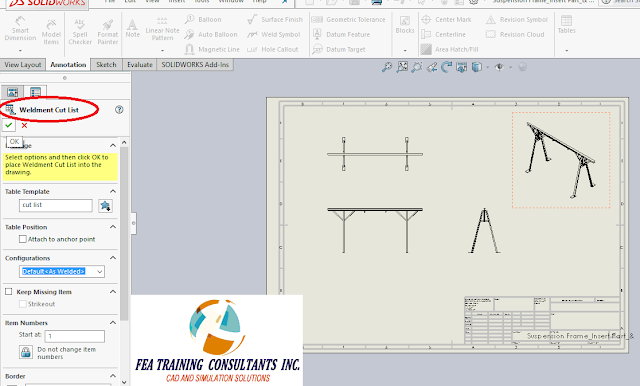

WELDMENT CUT LIST

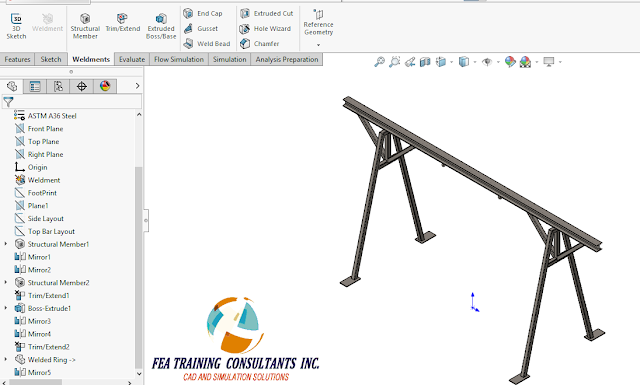

Last blog we explored the creation of a simple weldment frame. A natural extension to the weldment features is the cut list which lists all the parts and lengths required to make the weldment. It is very similar in nature to a bill of material. Consider our weldment frame:

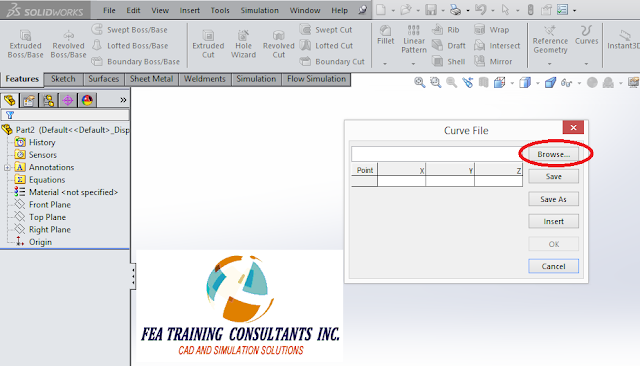

We’ll start

by creating a drawing for this weldment by first going to File> Make Drawing

from Part.

A simple

drawing is created with a plan, elevation, side and isometric view. Now we would like to insert our cut list.

In order to

insert a cut list go to Annotation> Tables > Weldment Cut List

In the

Weldment Cut List Property box, the designer is able to change and modify

various parameters such as the table name/ template, position, etc.

Once a table

has been completed, the designer will find a list of sections including

description, quantity, length and item number.

You might notice that there are special entries such as plate and

Weld-On Ring. The Weld-On Ring is a

special unique part therefore has a separate entry, however the plate was the

base plate we modeled. The cut list

conveniently lists the dimensions of the plate.

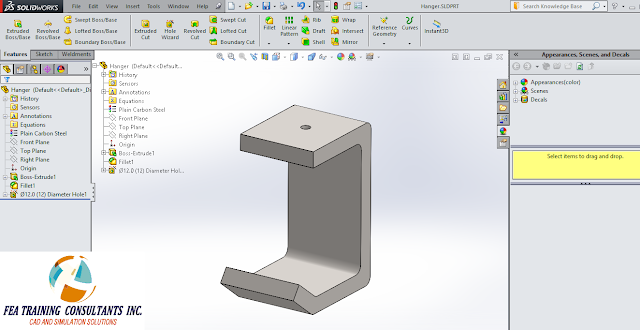

These dimensions are controlled by a bounding box.

If the

designer needs to make changes or even edit the bounding box, it is done simply

by going back to the model, expand the cut list and right click the part of

your choice and select Edit Bounding Box.

This is a very useful feature to capture items such as base plates,

stiffeners and gussets, all very common structural elements.

Weldment

features in SolidWorks makes designing quick and easier for designers. Weldment is available for all versions of

SolidWorks; Standard, Professional and Premium.