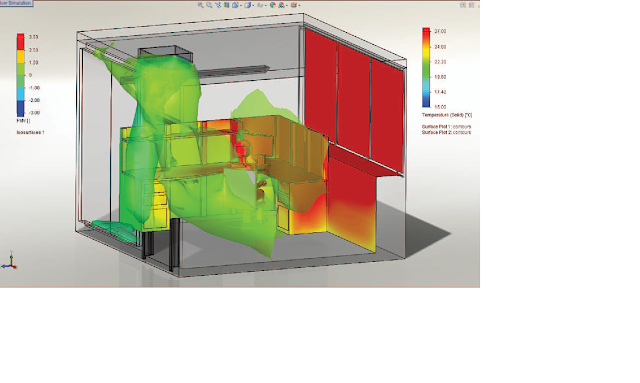

SolidWorks FlowSimulation is known to take out the complexity from computational fluid dynamics (CFD) – a technology which when put into

software enables mechanical engineers in stimulating fluid flow and heat

transfer applications using intuitive and powerful simulation tools.

There are numerous key benefits of using SolidWorks Flow Simulation which sets

it above the rest and gives you enough reasons to choose it over others. Such

reasons are what we will discuss in this blog today.

With the help of SolidWorks Flow Simulation Technology, you

can save a lot of time as in comparison to other traditional CFD Programs.

Where a traditional CFD program would take about two weeks to cover the process

of transfer and analysis, SolidWorks Flow Simulation Technology does it in

under fraction of days.

Reason number two is the possibility of analyzing complex

geometry with ease. With SolidWorks Flow Simulation you can easily handle CAD

geometries carrying tight crevices as well as sharp angles without having to

defeature the model. However, do note, if you happen to decide in favor of

simplifying your model you would need to access power simplification

geometrical features in order to prepare your model for CFD analysis.

Reason number three is the effortless ease with which this

software meshes. As you might have seen in standard CFD packages, getting an

optimum mesh is not easy. SolidWorks Flow Simulation, on the other hand,

provides robust automatic mesher for those fluid and solid regions.

.

These reasons provide a solid statement in favor of

SolidWorks Flow Simulation and why you must go for a SolidWorks Flow Simulation Training right away.