Case Study: Bolt Fracture

Hardware

such as bolts, nuts and washers are generally used for connections and

fixtures. They form an integral part of

the component structural integrity.

Bolts are governed by standards such as ASTM and are typically stamped

with an identifying marking on the head during the manufacturing process. The bolts selected for any application

typically take into account the manner in which it is applied while taking into

account the most prevalent mode of failure.

It follows that it would be in the designer’s best interest to

understand how bolts fail and to avoid those situations.

Roundhead

Bolt 12mm DIA x 152MM LONG ASTM A307

It is worth

noting that the tensile strength for that grade of bolt is approximately 60,000

PSI. Therefore, using plain carbon steel

as a template, the tensile strength was adjusted accordingly.

Next, we can

set up a test scenario using SolidWorks Simulation where the bolt is fixed at

the top with a base tensile load of 10,000 PSI applied at the bottom

We can now

mesh the bolt

After

running the Static analysis we can do a section plot to understand how the

stress a distributed in the cross section of the bolt. We find that the highest point of stress concentration

occurs at the neck as expected with a value of 28,067 PSI.

Note

that this value is fairly close to yield strength of the material 31,994

PSI. If a stress value approaches the

yield strength, the general assumption of linear behavior of the material

begins to breakdown. Therefore it is in

our best interest to run a non-linear analysis as well.

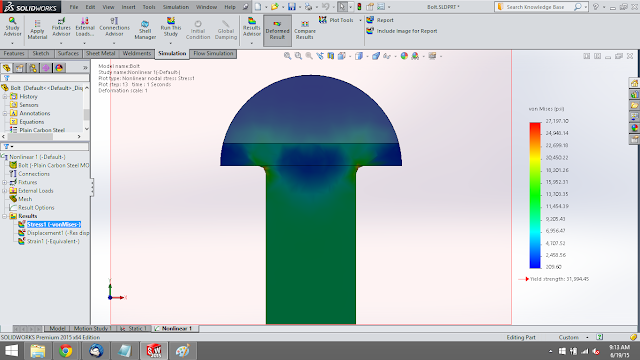

Creating a

new non-linear study and running a similar analysis we find that the actual

stress is approximately 27,197 PSI. This value is less than the linear analysis

but it is still close to yield.

Given these

results it would be in the designer’s best interest to either reduce the load,

increase the bolt diameter or chose a higher grade bolt.

Sometimes

bolt failure can occur due to other circumstances as well. Specifications such as how much a bolt must

be tensioned at installation can make a difference. In other cases large batches can yield bolts

with manufacturing defects which may fail below the yield stress.

No comments:

Post a Comment