Simulation Contact Set

SolidWorksSimulation of assemblies or multi bodies requires the application of contact

sets to define the interface between two objects. If the contact sets are not defined properly

we will obtain incorrect results.

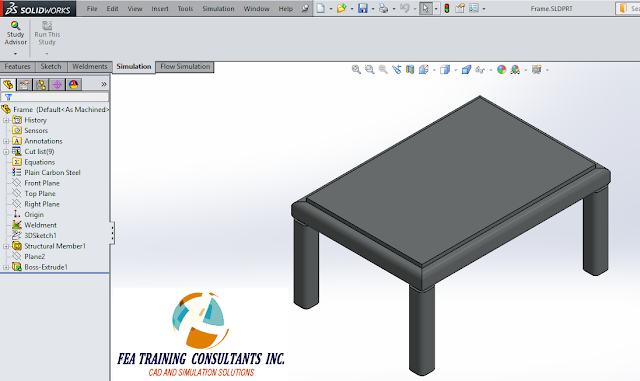

Consider a simple weldment framed structure

with a steel plate sitting on top.

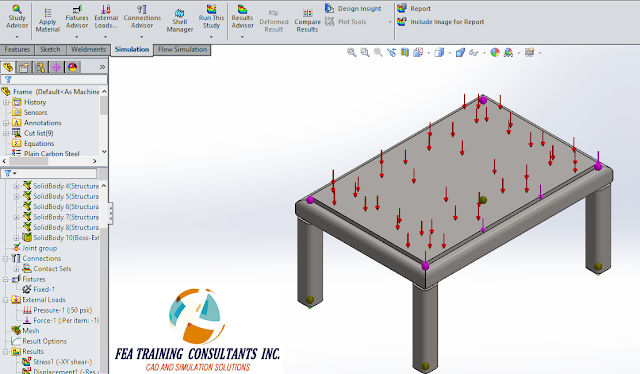

This

weldment is fixed at the end of each leg and has a load applied to the plate on

top.

By default,

SolidWorks Simulation treats weldments as beam elements and the plate on top as

a solid element. As such we have two

different element types in this analysis; therefore we need to define a contact

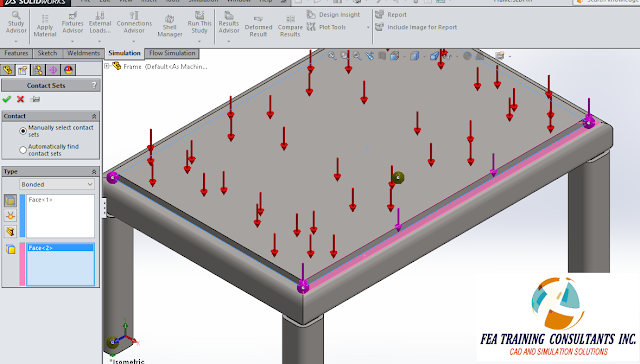

set. As an option we can use the

“automatically find contact set” function by selecting a beam element and the

plate. The software will find the

connecting surface where you may apply a condition, in this case bonded. This is repeated for all four faces.

Upon closer

inspection, we find those contact sets to be a face to face contact

Following

the creation of the contact sets we can mesh our model and run the analysis

However in

doing so will result in an error message.

This is

because the contact set defined was incorrect.

When the contact sets were created they were treated as faces, however

since this is a solid to a beam element, we need to select the beam element

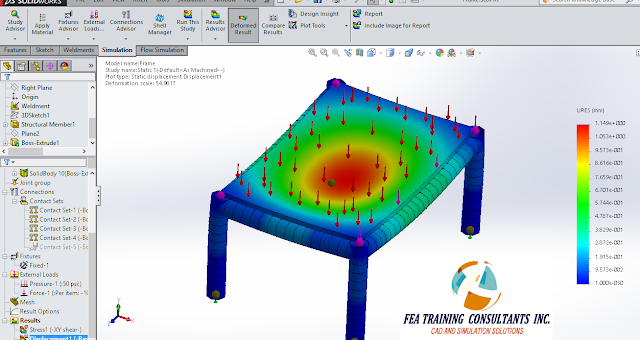

contact set under “Type”. By redefining

all four contact sets, remeshing and running the study, we now have the correct

results.

No comments:

Post a Comment